What is MES?

These days we live in a world where we give priority to ”buzzwords”. These are terms that become popular for a brief period of time and typically arise from technological advancements, business strategies or other areas of interest. Once many people are using and talking about it, the interest in learning more about these concepts is huge.

One of the terms we can consider as a buzzword is MES, which stands for Manufacturing Execution System. Such a system has the main goals of mapping, monitoring and controlling complex manufacturing processes with real-time data.

Although an important concept, as many people and industries use it, over time different interpretations of its meaning have emerged. Let’s clarify details to help you understand and implement it appropriately.

Start Your Project NowAutomation Pyramid

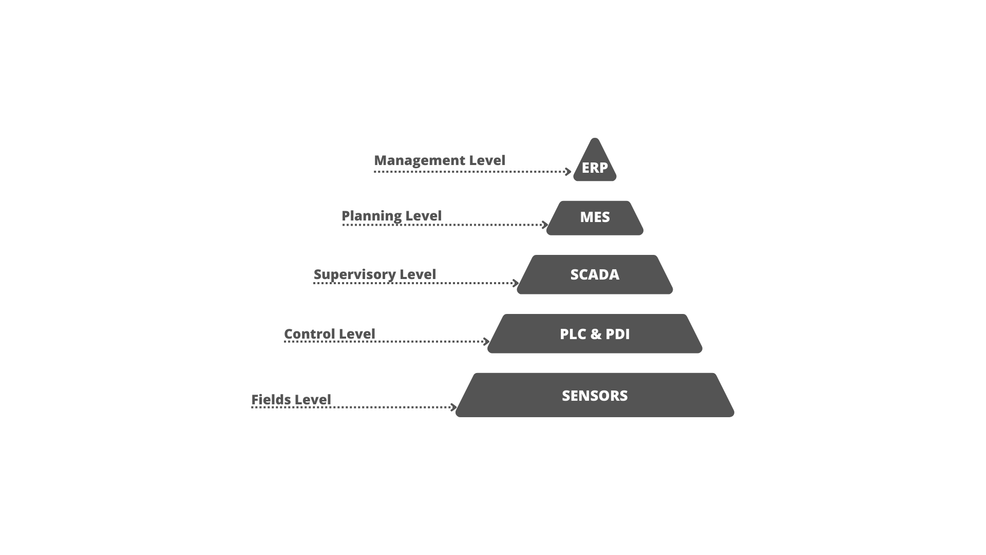

Let’s start with the basics. The best way to understand and distinguish all the systems that might exist in an industry is by analyzing the automation pyramid.

- Fields level: Distributed through the shopfloor you might have multiple sensors or other similar devices to capture some parameters of your process. (E.g. temperature sensor)

- Control level: This includes the PLCs and PIDs that control and “run” the devices. They use the information from the sensors to make decisions on what outputs to turn on to complete the programmed tasks. (E.g. If temperature rises to 100ºC, turn off the heater)

- Supervisory level: To monitor and control the previous systems from a single location, it is used SCADA, which means Supervisory Control and Data Acquisition.

- Planning level: It is on this level that MES is used. MES will monitor the entire manufacturing process of the shopfloor, which allows management teams to see exactly what is happening in real-time and make decisions based on that information.

- Management level: The ERP is at the top of the hierarchy. It allows monitoring of all levels of the business from Manufacturing to Sales, Purchase and more.

Different Concepts

As MES and ERP are both for management, it can create confusion. For one thing, because of minor overlapping, some find it difficult to distinguish between these two concepts.

To help you define each one, view the main characteristics below:

ERP - Enterprise Resource Planning

- Encompasses all business operations

- Captures operational and finance data in real-time for both immediate and long-term analysis

- Is triggered by operational and accounting events

- It is integrated with other software systems within the company

MES - Manufacturing Execution System

- The focus is on manufacturing operations

- Captures factory-floor data in real-time for immediate analysis

- Is triggered by manufacturing events

- It is integrated directly with the devices on the shopfloor

Discover More About Odoo & Manufacturing

ODOO MES

In Odoo there is a module dedicated to manufacturing processes called Manufacturing, also known as the MES module.

Above we defined the concepts of ERP and MES as two different systems with their own objectives. However, it is possible to find most of the characteristics of a Manufacturing Execution System in the Odoo Manufacturing module and that’s why we can consider this module as an MES module. The new features released in V16 that can belong to the main characteristics of a MES are:

Manufacturing Operations Focus

- It is now possible to merge and split MOs and also to set dependencies between the operations. This improves tracking and scheduling capabilities to enhance work order management.

- There is a new panel instructions overview on WO with status information.

- Improve bill of materials (BOM) management with the new BOM overview. This allows easy tracking of component quantities and availability.

Real-time Data Capture and Integration with Shopfloor Devices

- Integration with measurement equipment to record precise measurements and data for quality assurance.

- Automatic recording of production times due to easy login and multi-user capability.

Triggered by Manufacturing Events

- It releases the related Work Orders once the pre-production pickings are finished and the components are ready for assembly.

- Feedback loop for continuous improvement that automatically creates Engineering Change Orders (ECO).

View more Odoo V16 features

Conclusion

Overall, MES plays a vital role in modern manufacturing processes by providing real-time visibility, control, and optimization. With the Odoo MES module, you’ll know:

- What to do, through automatic job releases

- When to do it, through optimized job scheduling

- How to do it, by providing real-time instructions and feedback

Do you want guidance on how to implement Odoo MES? Do you have any more questions on how this system can work for you? Our team is available to assist!

Start Your Project Now